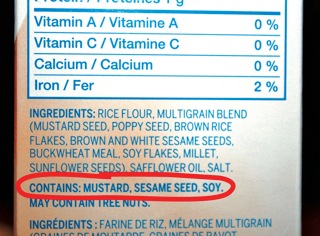

1 reason for product recalls in the food industry world-wide. Hence it is important to give proper attention to all food that starts with g aspects involved in the management and prevention of allergens before, during and after the food production process. Like many other concepts, allergen prevention and management will only work properly if ALL aspects are properly controlled at all times.

In this article we will highlight the seven important areas for allergen management. Raw Material Management All food products start with their raw materials. It is paramount for any company to really understand all the details of the raw materials they use. Make sure you do not only ask your supplier for an allergen statement from their side, indicating those allergens which are present in the material. Also ask your supplier for any allergens which are used in their manufacturing location and take this into equation as well.

It is important to pay special attention to suppliers that are manufacturing constituted food stuffs of multiple ingredients to see if they in their turn have their act together as well. You really want to make sure that these supplier really understand and execute your requirements when it comes to allergen management. Especially suppliers of herbs and spices and dry powder mixers are good examples of this category. In a warehouse it is important to physically segregate materials containing allergens from those not containing allergens. The best solution for this is to have separate warehouses or at least two separate storage locations in one warehouse.

The second important item when it comes to storage is to always make sure allergens are stored on the floor only. Transportation even more that storage can be a time when cross contamination might occur. Try to arrange transport in such a way that products with incompatible allergen profiles are transported separately. The first step in the proper management of information in relation to allergens is to manage your recipe information in a flawless manner.

You can make use of dedicated software to do this. Many ERP systems already have this functionality built in or you can buy it as an additional option. Applying the wrong label is one of the single highest causes of recalls related to allergens. Managing the labels physically is as important as managing the information on the labels.

In your warehouse set-up try to ensure that similar labels are placed as distant from each other as possible. Alternatively, you should use fully randomized material numbers for your labels, thus forcing the warehouse staff to really picking the right materials. Have two operators cross check whether they are using the right label before the production run starts. MES or alternatively again by two independent operators in connection to the previous point. Minors Dosing In most companies the dosing of minor ingredients is a totally manual process. When weighing minor ingredients always use separate, clean bags to weigh the raw material into.

This way you will prevent cross contamination via to balance tray. Ensure to properly close each bag before placing it next to other bags intended for the same production run. In order to prevent mixing up of bags of minor ingredients always work on one batch or one single product at one time when pre-weighing the minor ingredients. Hence other principles must be applied. Good allergen management starts of course with the planning department. The best way to reduce the risk of cross contamination of allergens in the production area is to start after a full deep cleaning with products containing no allergens.